Various defects that may exist in

silicone tubing include extruding lines or gels, which may be caused by premature solidification in extruders. Bubbles (moisture may be absorbed by cooling roller of double roller to form water vapor during solidification, or H-Si ≡ may react with hydroxyl substance in platinum curing product to form hydrogen); Particulate pollution.

It is not easy to determine the limits for these defects, but they are detailed in the sales specification. ISO standards related to silicone elastomers for hose extrusion even refer to some visual inspection. Other issues related to mechanical properties involve floor space and handling. The problem here is to "manage" the hose in pharmaceutical production with minimum floor space, while avoiding kinking and other problems. The variables to be considered include the bending radius (the radius of the hose bend measured on the innermost surface of the bend) and the bending force (the stress required to bend to the specified radius).

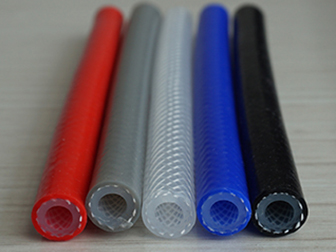

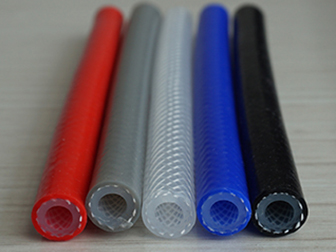

Sometimes the silicone tube can be marked by external printing, but due to its low surface energy and poor ink adhesion, it can be easily erased in the process of cleaning with common solvents. Organic silicon can also mix colors. Barium sulfate is often used as white filler for base color mixing, or for coextrusion strip of X-ray impermeable medical devices.

SUNRISE is an ISO9001 certified silicone tube manufacturer. We specialize in supplying various silicone hose, silicone tubing! Welcome to custom silicone tubing, including size, color, and special performance requirements.

Related Products: Colored Silicone Tubing,Extruded Silicone Tubing